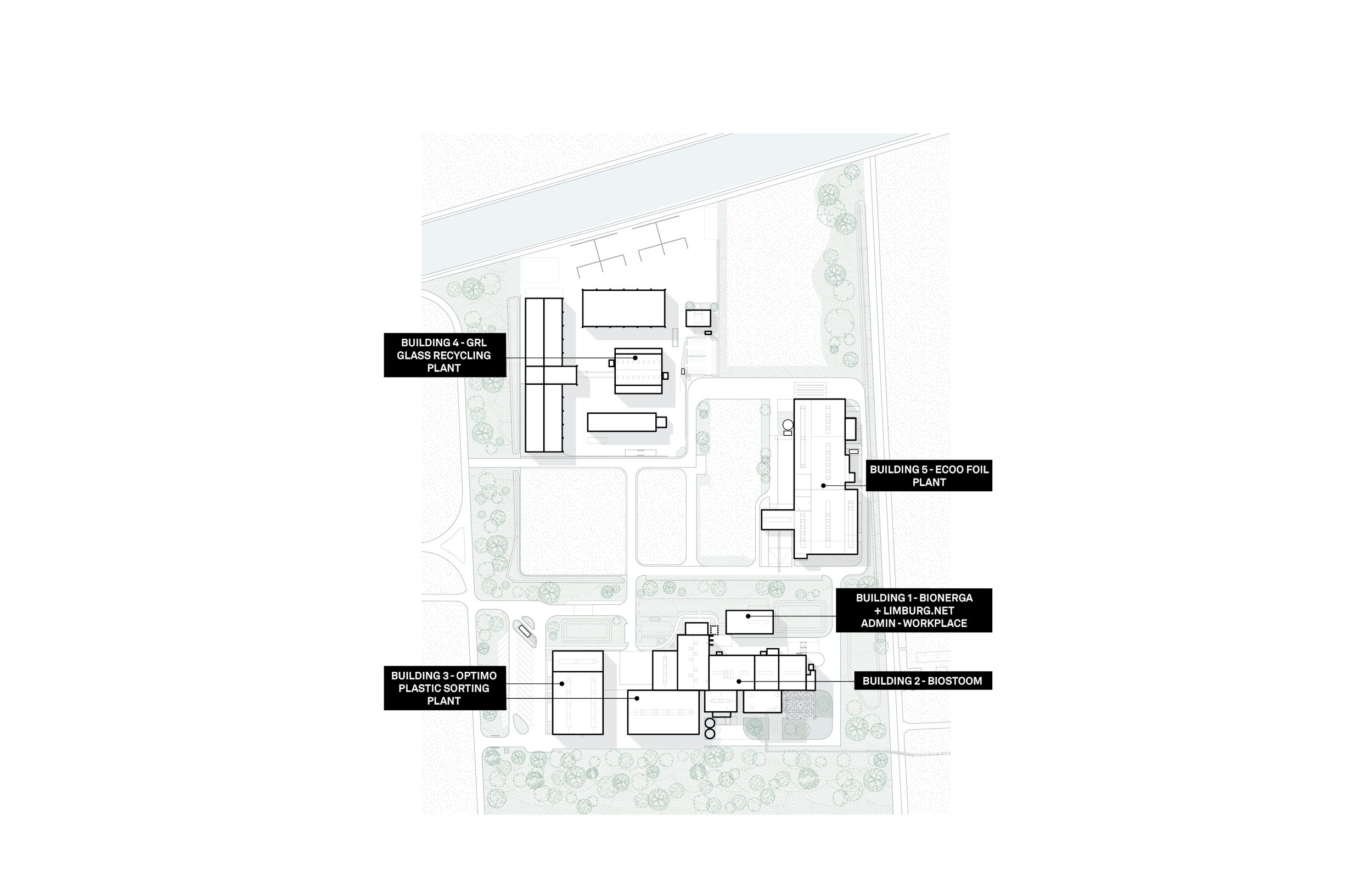

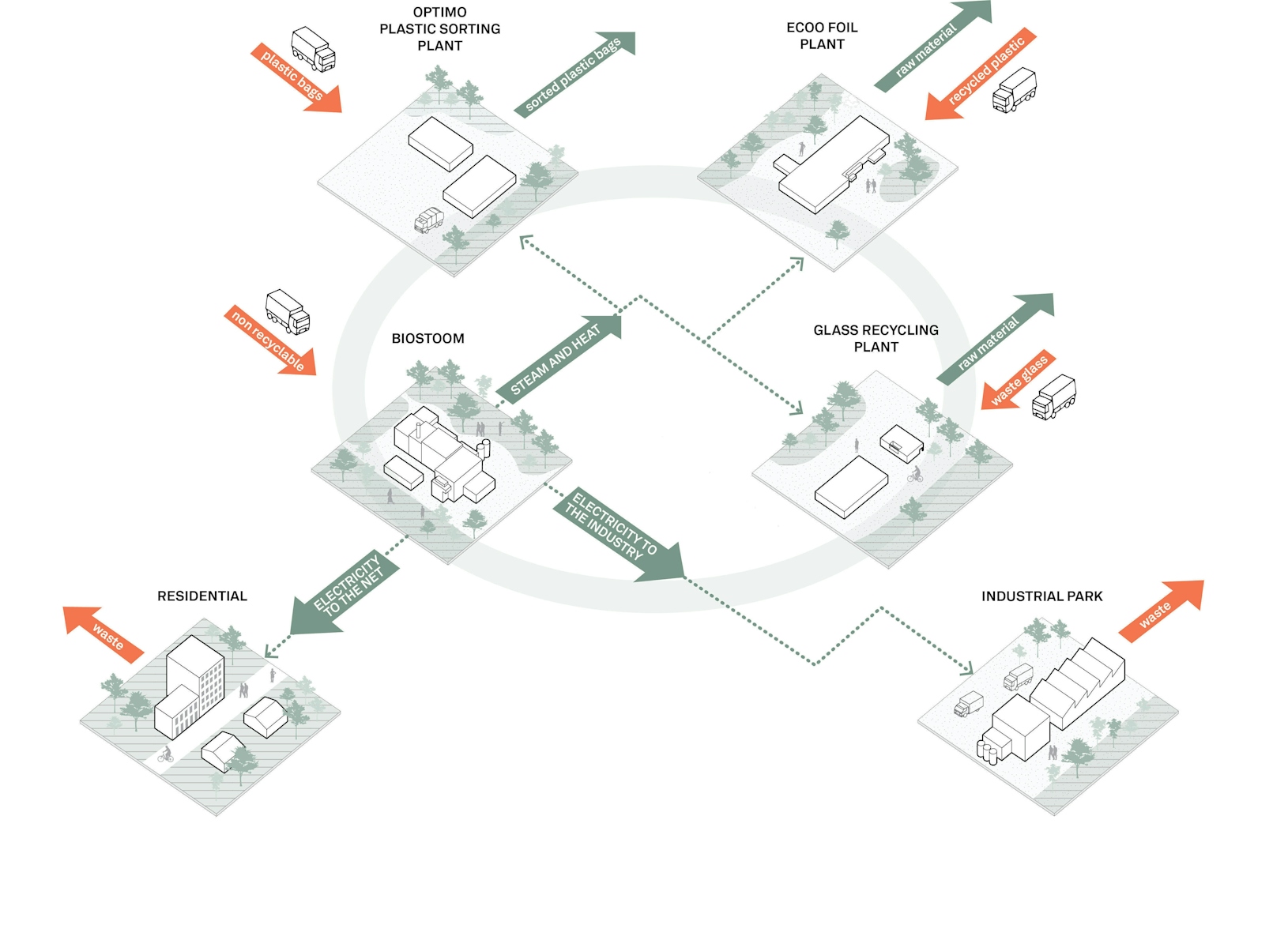

Among those are the Biosteam Beringen plant of Bionerga NV, the GRL Glass Recycling & Logistics plant, the Optimo Biosort Beringen plant of Bionerga NV, the ECOO Foil plant and the Bionerga and Limburg.net administration and workplace center.

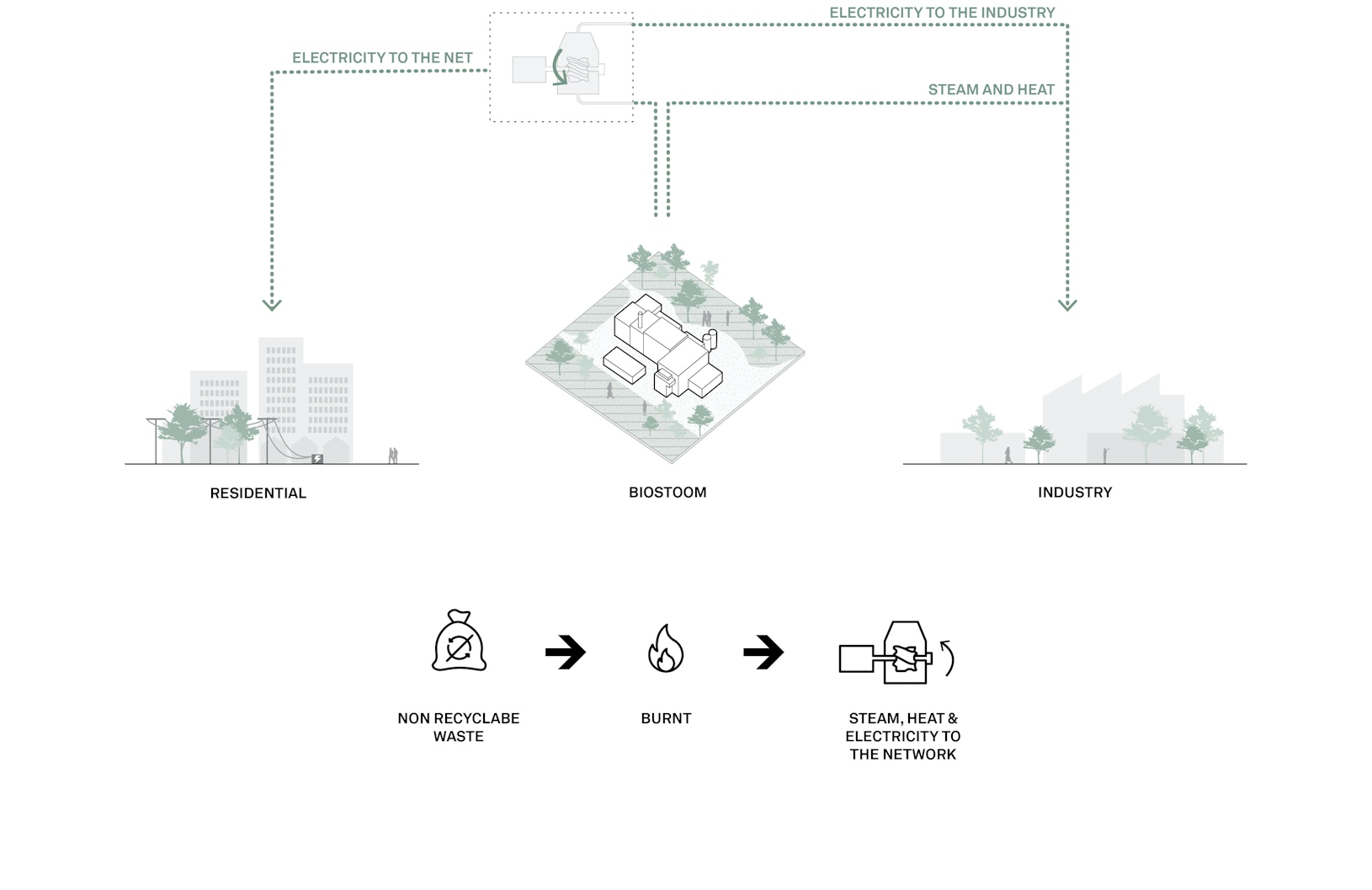

Biosteam Beringen

RECEIVING AND BURNING

Household residual waste and similar commercial waste is delivered by truck and incinerated at about 1000°C.

ENERGY

Combustion creates thermal energy. This can be supplied in the form of steam or hot water to nearby businesses or converted into electricity.

SMOKE GAS PURIFICATION

The flue gases from the biosteam plant go through several purification steps before being emitted into the atmosphere.

EMISSION MEASUREMENTS

The purified flue gases are finally emitted into the atmosphere through a chimney. Measuring instruments are placed in the chimney to permanently measure the quality of the flue gases and test them against the legal emission standards.

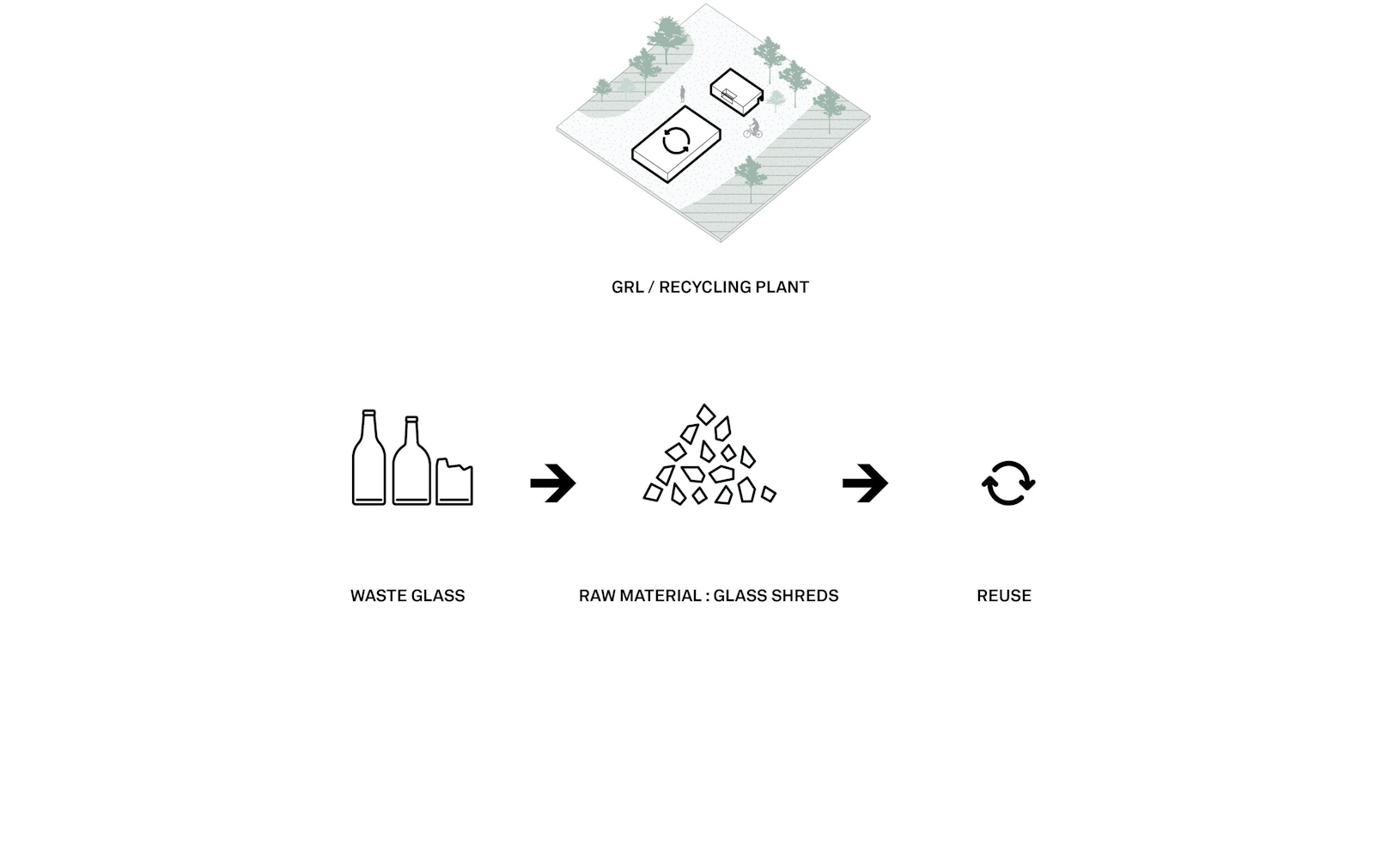

GRL Glass Recycling

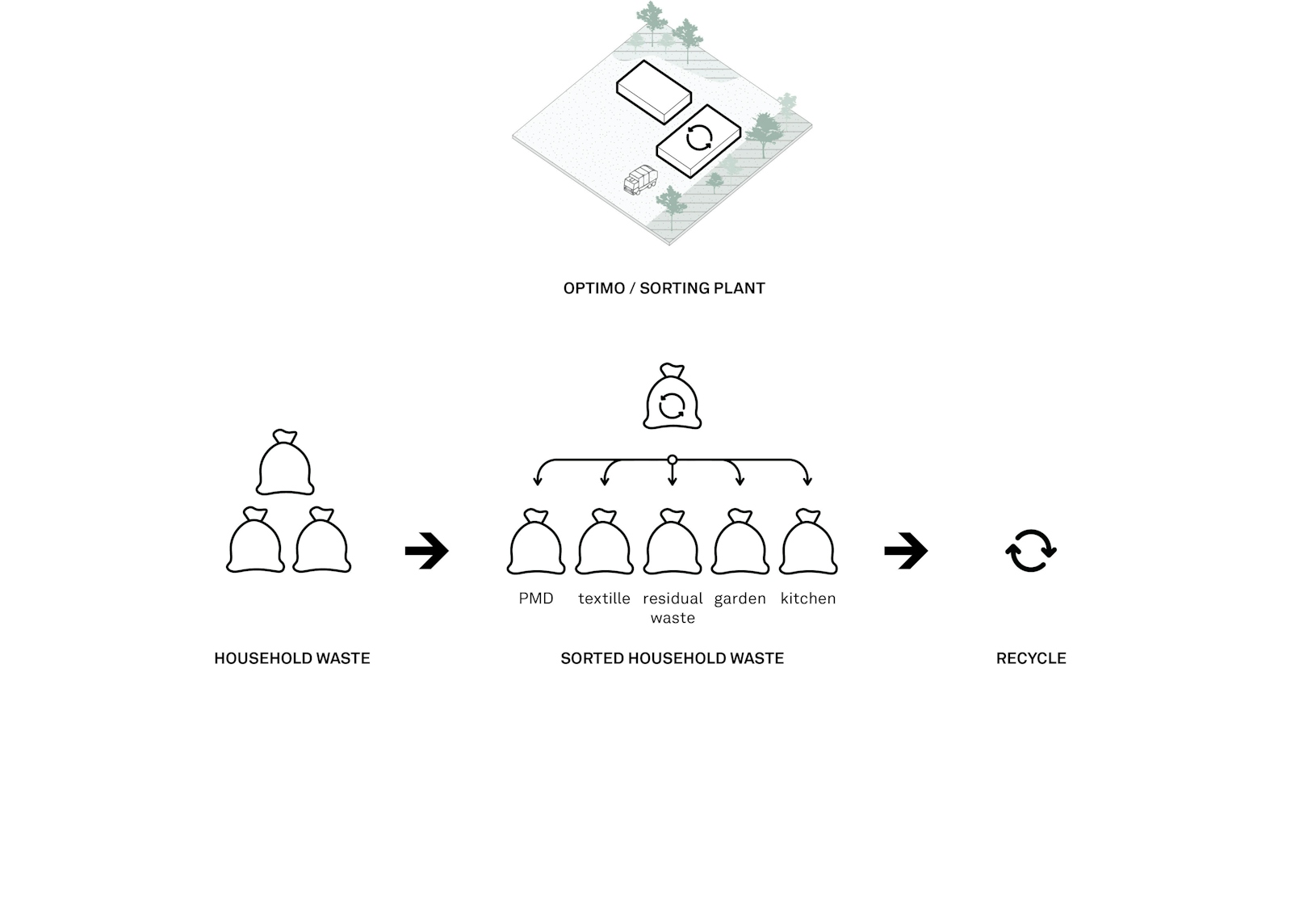

Optimo Sorting Plant

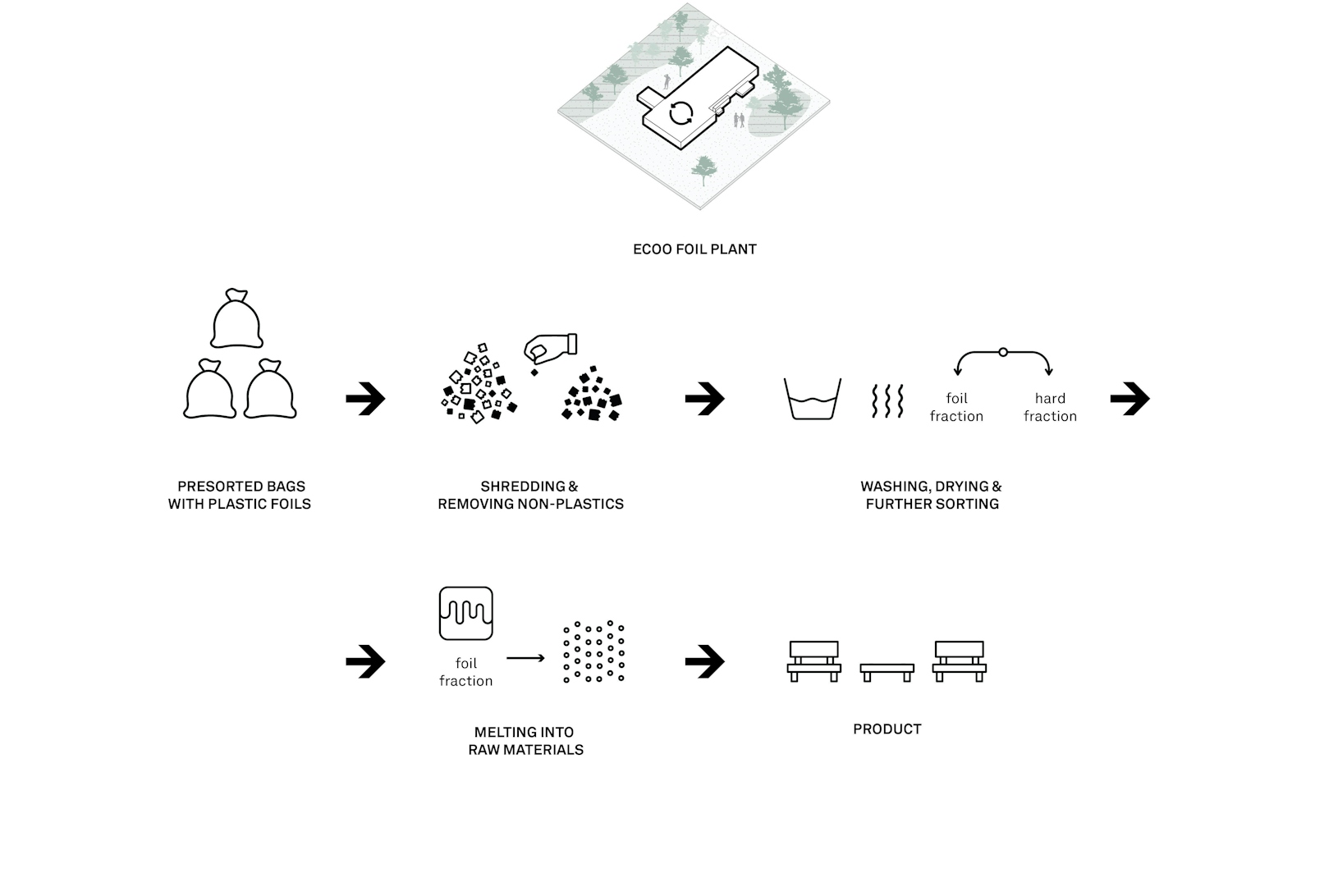

Ecoo Foil Plant

Pictures and video GRL: Karen Van der Biest